Concrete is one of the most important substances on earth. After water, it is the most consumed product on earth. Yet it’s key ingredient – cement – is extremely polluting. It is responsible for over 90 per cent of the carbon footprint of concrete. Overall, every tonne of cement manufactured emits almost one tonne of CO2.

Ecocem is a pioneer of high-performance cement technology for the deep and rapid decarbonisation of the cement and concrete industries. This technology has the potential to reduce the carbon footprint of the cement industry by as much as 70%

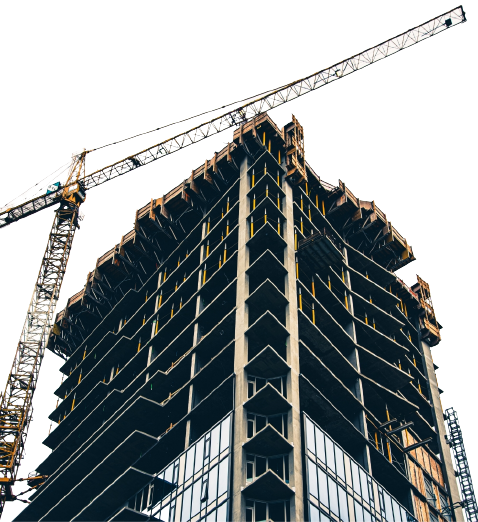

The world needs cement. From housing, sanitation, and places of education and health to roads, flood defences and sustainable energy sources, cement is the glue that holds it all together.

Ecocem Founder and Managing Director, Donal O’Riain attended the Construction Clean Transition Dialogue, hosted by EU Commissioner for Climate Action, Wopke Hoekstra, and shares his insights on the need for Europe to lead by example in sustainable construction.

Ecocem, Europe’s leading provider of low carbon cement technologies, today announces it has agreed a deal with Overslagbedrijf Moerdijk (OBM) to expand production and storage capacity in The Netherlands to accelerate bringing its ACT technology to market.

Founder and Managing Director, Donal O’Riain, shares his views following the first UNEP Buildings and Climate Global Forum organised jointly with the French Government.

ACT, Ecocem’s groundbreaking low carbon cement technology, has been selected to showcase at The Buildings and Climate Global Forum – a first-of-its-kind event that will build on the progress made at the recent United Nations Climate Change Conference (COP28).