Concrete is one of the most important substances on earth. After water, it is the most consumed product on earth. Yet it’s key ingredient – cement – is extremely polluting. It is responsible for over 90 per cent of the carbon footprint of concrete. Overall, every tonne of cement manufactured emits almost one tonne of CO2.

Ecocem is a pioneer of high-performance cement technology for the deep and rapid decarbonisation of the cement and concrete industries. This technology has the potential to reduce the carbon footprint of the cement industry by as much as 70%

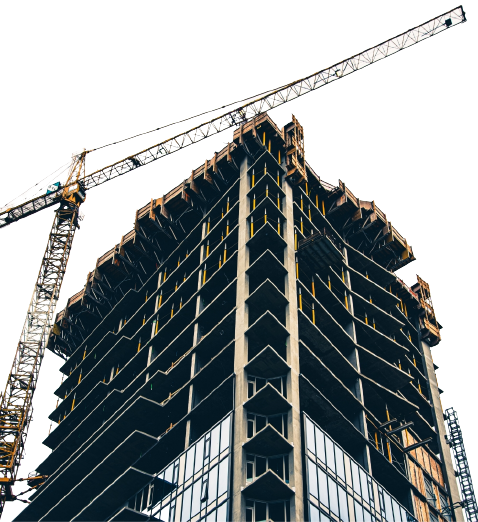

The world needs cement. From housing, sanitation, and places of education and health to roads, flood defences and sustainable energy sources, cement is the glue that holds it all together.

Ecocem has obtained a Technical Evaluation of Products and Materials (Evaluation Technique de Produits et Matériaux, or ETPM) in the French market for ACT1 – the first version of our groundbreaking scalable cement technology.

This investment is in addition to the €50 million investment at Ecocem’s Dunkirk facility to deliver its first ACT production line. These new industrial facilities will be concentrated in the Fos-sur-Mer and Dunkirk areas.

In his latest blog, Ecocem’s award-winning research scientist, Simon Blotevogel, speaks about research on Electric Arc-Furnace (EAF) slags, collaboration being the key to innovation, and how we are at a critical moment in our mission to decarbonise the cement industry.

John Reddy, Director of Concrete Technology Deployment at Ecocem, reflects on his recent Webinar with the NEU, a centre of excellence for carbon-neutral concrete established by the American Concrete Institute (ACI)