Reflecting on the recent Breakthrough Energy Summit I attended in London, I was absolutely blown away by the huge progress made with decarbonization technologies. I was struck by the energy and commitment of everyone I met to deliver scalable solutions that can tackle our climate challenge at speed. At a time when the problems we face can seem insurmountable it was good to be reminded that the technology we need already exists. Bill Gates is right: The green revolution is in full swing. Now we need to commit to the changes we need to make to accelerate adoption. And my own industry is no exception.

I spoke at a session on solving for carbon in the Built Environment, which focused on Embodied and Operational emissions. I called on industry, governments and policy-makers to work together to raise our ambitions for the cement industry to become the first hard-to-abate industrial sector to deliver decarbonization on a trajectory compliant with a 1.5°C target. This requires a global decarbonization of cement manufacture of 50% by 2030 (IPCC 2023).

From Le Grand Paris Express to Dublin’s Aviva Stadium, and the UK’s high-speed railway HS2, our company has already achieved a cumulative reduction of 18 million tonnes of CO2 to date. To put this in perspective, it would take over 800 million trees to capture this amount of CO2 in a year.

Let’s be clear about the scale of the problem with cement.

If the cement industry were a country, it would be the third-largest emitter of carbon dioxide on the planet, after the US and China and significantly ahead of the EU. Responsible for almost 8% of global carbon emissions, cement production is recognized as one of the most polluting industries in the world.

Embodied CO2 in construction is 11% of all global emissions, and clinker, the critical ingredient in cement, generates 65% of these. On average a tonne of cement produces 600Kg of CO2. The bulk of these emissions is the unavoidable by-product of clinker manufacture. The solution lies in eradicating as much CO2 as possible from the manufacturing process by using less clinker. Rapid and sustained decarbonization of this sector would make a meaningful difference in the battle against climate change. Radically reducing cement’s clinker content is the most logical decarbonization pathway.

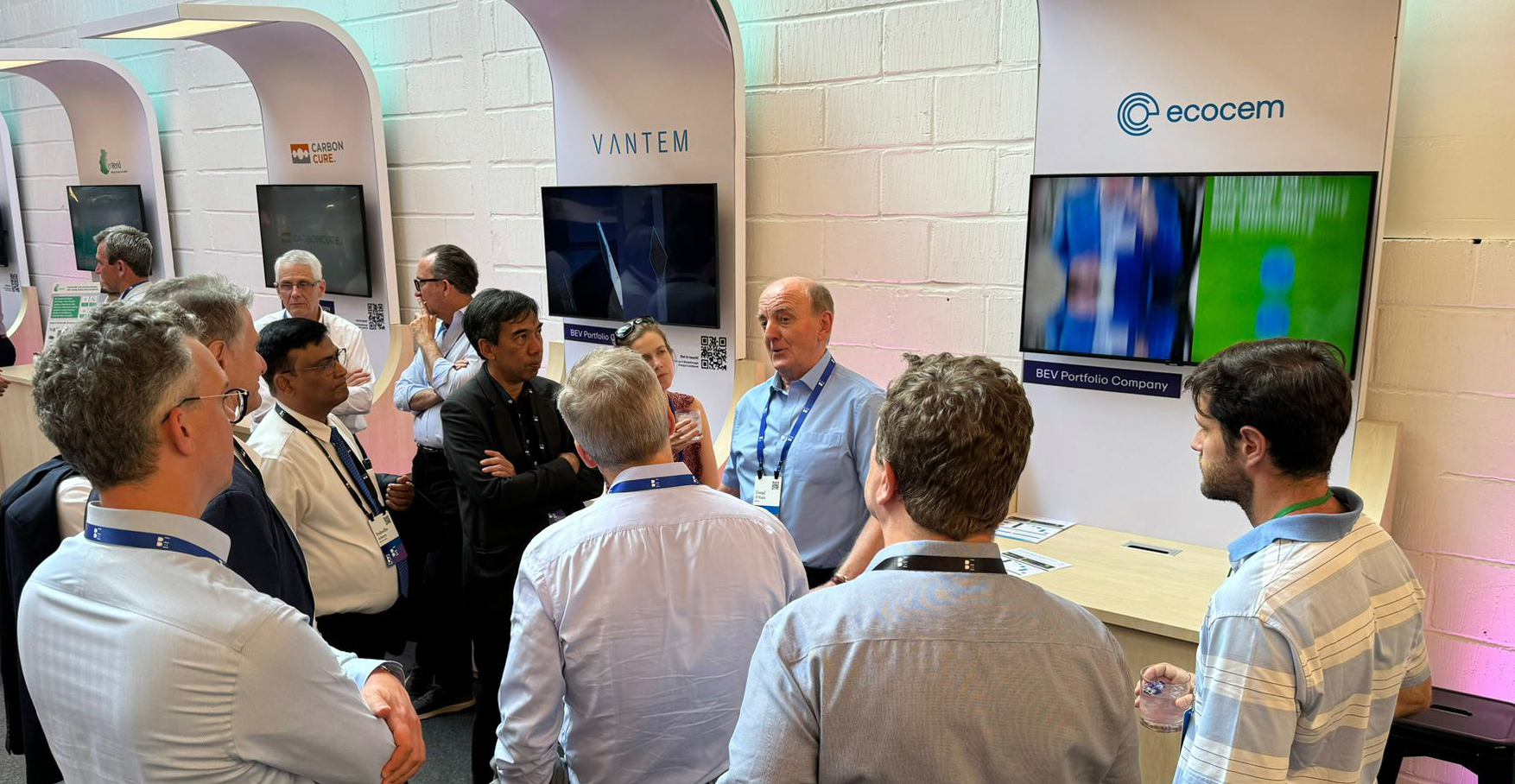

Ecocem’s Founder and Managing Director, Donal O’Riain, presenting at a discussion on Solving for the Built Environment focusing on Embodied and Operational Carbon at the Breakthrough Energy Summit 2024.

We already have the solutions.

The problem is enormous, but the good news is that technology exists today that can deliver a 70% reduction in clinker use, and as a result CO2 emissions. Our ACT technology can do this competitively while delivering all the performance requirements of any concrete it is used to make. Most importantly the technology can do this globally and at scale.

Speed is of the essence and fast-tracking solutions is essential. The cost is not a barrier. Shifting to manufacturing low carbon cement using this technology requires no major change

to current plant infrastructure and uses raw materials, energy and water with much greater efficiency.

What is needed now to make this a reality for the rest of the industry?

The key is overcoming industry inertia. Changing a deeply embedded, economically viable, but heavily polluting business model remains challenging.

As an industry we need to look at a range of technologies. Our current industry focus on a single solution is limiting us. Carbon Capture and Storage will at best be a limited solution for economic and environmental reasons: too slow to deliver and too expensive. The construction industry needs to adopt the low carbon cement technologies that enable business to control costs and become more competitive.

We must reset our ambition – will we step up to the challenge?

As I have outlined, the cement industry can become the first hard-to-abate industrial sector to decarbonize on a trajectory compliant with 1.5°C of global warming. We can achieve a 50% reduction in carbon emissions globally by 2030, reach a 100% reduction by 2040, with negative emissions post-2040.

The need to fast-track decarbonization is obvious and urgent. The global cement industry now has the technology for rapid and low-cost reduction of CO2 emissions. We must seize this opportunity and here at Ecocem we will continue to lead the way on cement decarbonization technologies with renewed determination and enthusiasm.

Conor O’Riain, our European Managing Director, with Ecocem Founder and Group Managing Director, Donal O’Riain, at the Breakthrough Energy Summit 2024.

Reflecting on the recent 2025 IEEE-IAS/PCA Cement Conference, Ecocem’s Steve Bryan digs into why the United States’ ability to meet growing demand for cement domestically is likely to fall short—and what to do about it.

In his latest blog, Ecocem’s award-winning research scientist, Simon Blotevogel, speaks about research on Electric Arc-Furnace (EAF) slags, collaboration being the key to innovation, and how we are at a critical moment in our mission to decarbonise the cement industry.